Wiping die bending also known as edge bending is performed by holding the sheet between a pad and die then sliding the wiping flange across the face pushing and bending the sheet metal which protrudes from the pad and die.

Restrike operation in sheet metal.

Sheet metal operation part 1 sheet metal design series duration.

These dies also referred to as qualifying dies usually use tension to re form the part.

The restraining force is provided by the blank holder or draw bead to control the material flow rate and the force is created by friction between the blank tooling.

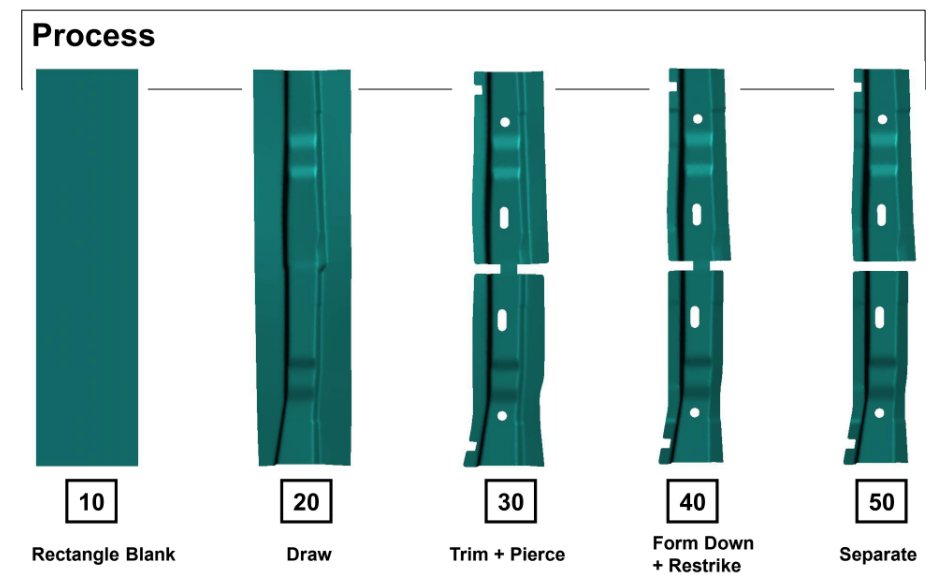

In this case what you have is a metal blank.

The flange is driven by an upper shoe and the die is supported by a lower shoe.

7 essential knots you need to know duration.

Experimental sample after emf restrike operation.

It is a shearing operation in which blanks are separated from a sheet metal strip by cutting the opposite sides of the part in sequence.

It s a piece of sheet metal devoid of manipulation or change.

In most cases the metal blank is comprised of steel sheet metal.

However filling both trihedral corners required much material elongation substantially above the forming limit of aluminum sheet and also required much more pressure to fill the trihedral corner.

The middle portion of the sharp corner at the bottom of the cavity is filled.

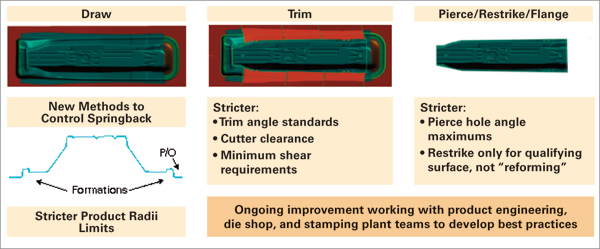

A restrike die operation often follows a drawing or trimming operation.

Die stamping involves using a special machine called a die to form trim flang emboss pierce or restrike that metal blank turning it into a new design.

Creo has the symbols for indicating bend direction and angle but things like bend relief forms puches or dies can only be defined by detailing.

Position of draw bead.

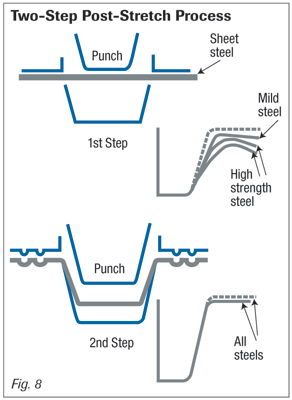

Smaller radii were used in the restrike step in order to significantly alter the deformation and the sprung shape.

Bending can be defined simply as a forming operation in which the metal is deformed along a straight axis.

Relief forms and die symbols for sheet metal i have googled extensively and have not found any references to any drawing symbols for use in specifying sheet metal operations.

Design hub recommended for you.

Additional panels were drawn to failure during both the first draw and the redraw in order to set the parameters for the springback trials and to demonstrate that a sheet metal going through a restrike operation can exceed conventional forming limits of that under a simple draw operation.

Trapped stress is the result of permanent metal deformation and it is the fundamental reason for a loss of flatness.

Trying to stop the stress from being created during the cutting or bending operation would be an attempt to defy physics.

The trihedral corners are not filled completely.

However compression also can be used.