Sheet resistance often called sheet resistivity is a measure of resistance of thin films that are nominally uniform in thickness.

Resistance of a 3 micron thick sheet of copper.

If your target finished copper thickness is 1 oz we ll start with a oz sheet of material.

The pressure drop caused by the line resistance generated by the length of the wire must also be considered in the experiment.

This is oz on each side.

70 microns thick 1 oz 0 035mm 1mil.

Copper sheeting comes in thicknesses ranging from very thin copper foil to thick copper plate.

Doped semiconductor regions e g silicon or polysilicon and the resistors that are screen.

When specifying the thickness of copper on printed circuit boards pcbs the usual metric is ounces.

For example the thickness of 12 ounce copper is such that every square foot weighs 12 ounces.

Because the production panels are completely covered with copper the excess copper needs to be removed to reveal your design.

The thickness of sheet and strip copper is measured by its weight in ounces per square foot.

If that trace is 1 2 ounce copper the dc resistance would be 1000 squares x 1 0.

To do this a 1 1 size image of your design is photo plotted onto a film.

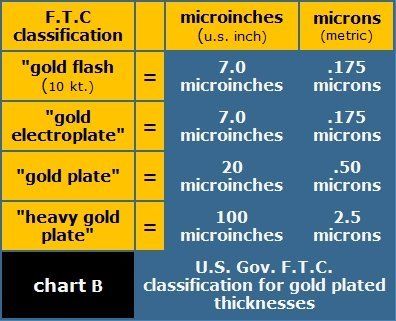

The table also shows the approximate resistance per square which is the edge to edge sheet resistance of any size square area of that weight of copper.

Copper 35 microns thick 2 oz.

The unit of line width is inch inch 25 4 millimeters mm 1 oz.

Below is a quick guide to help you determine which thickness best suits the needs of your project.